3D Printing in Defence Manufacturing: The Role of WAAM

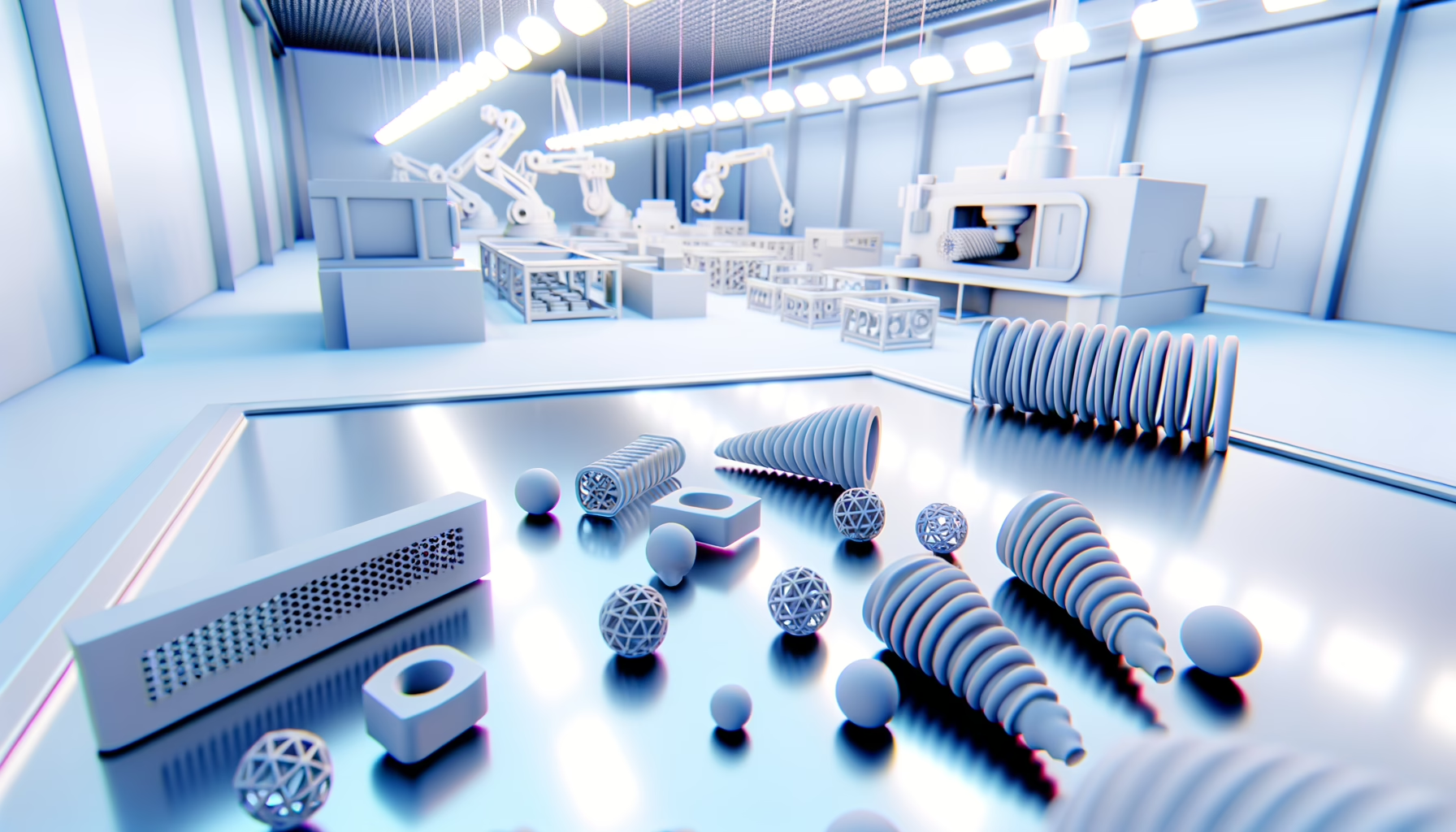

3D printing, or additive manufacturing, is revolutionising industries worldwide, and the defence sector is no exception. But why should we care? In the UK, where military budgets are scrutinised, the ability to produce components quickly and cost-effectively is a game-changer. This is where Wire Arc Additive Manufacturing (WAAM) comes into play. Let’s dive into how this technology is reshaping defence manufacturing.

The Significance of WAAM in Defence

WAAM is a type of 3D printing that uses an electric arc as a heat source to melt metal wire, layer by layer, to create components. It’s particularly useful for producing large, complex metal parts. Why does this matter for defence? Simply put, it allows for the rapid production of parts that are often expensive and time-consuming to manufacture using traditional methods.

- Cost Efficiency: Traditional manufacturing processes can be costly, especially for bespoke or low-volume parts. WAAM reduces material waste and lowers production costs.

- Speed: The ability to produce parts on-demand significantly reduces lead times. Imagine needing a replacement part for a military vehicle in the field; WAAM can deliver it faster than conventional methods.

- Complexity and Customisation: WAAM can produce complex geometries that would be difficult or impossible to achieve with traditional manufacturing.

Applications in the Military

The military’s use of 3D printing isn’t just theoretical. It’s happening now. Here are some practical applications:

- Replacement Parts: The US Army has been using 3D printing to replicate obsolete parts for combat vehicles. The same approach can be applied to ageing UK military equipment.

- Lightweight Materials: Research into lightweight materials for combat vehicles is ongoing. WAAM can produce these materials, potentially reducing vehicle weight and improving fuel efficiency.

- Field Applications: Imagine a scenario where a part breaks during a mission. With portable 3D printers, parts can be manufactured on-site, minimising downtime.

Challenges and Considerations

Of course, it’s not all smooth sailing. There are challenges to consider:

- Material Limitations: Not all materials are suitable for WAAM. The technology is primarily used for metals, which might not cover all needs.

- Quality Control: Ensuring the quality and reliability of 3D printed parts is crucial, especially in defence applications where failure is not an option.

- Integration with Existing Systems: Incorporating 3D printing into existing supply chains and maintenance operations requires careful planning.

Final Thoughts

If you’re involved in defence manufacturing, it’s time to get familiar with WAAM. Its ability to produce complex, customised parts quickly and cost-effectively is unmatched. But be aware of its limitations.

Not every part can be 3D printed, and quality control remains a top priority. If you’re not considering 3D printing in your operations, you might be left behind. I’ve hit this myself in various projects, and the benefits are clear. But remember, unless your setup’s odd, integrating WAAM into your operations will likely require some adjustments.