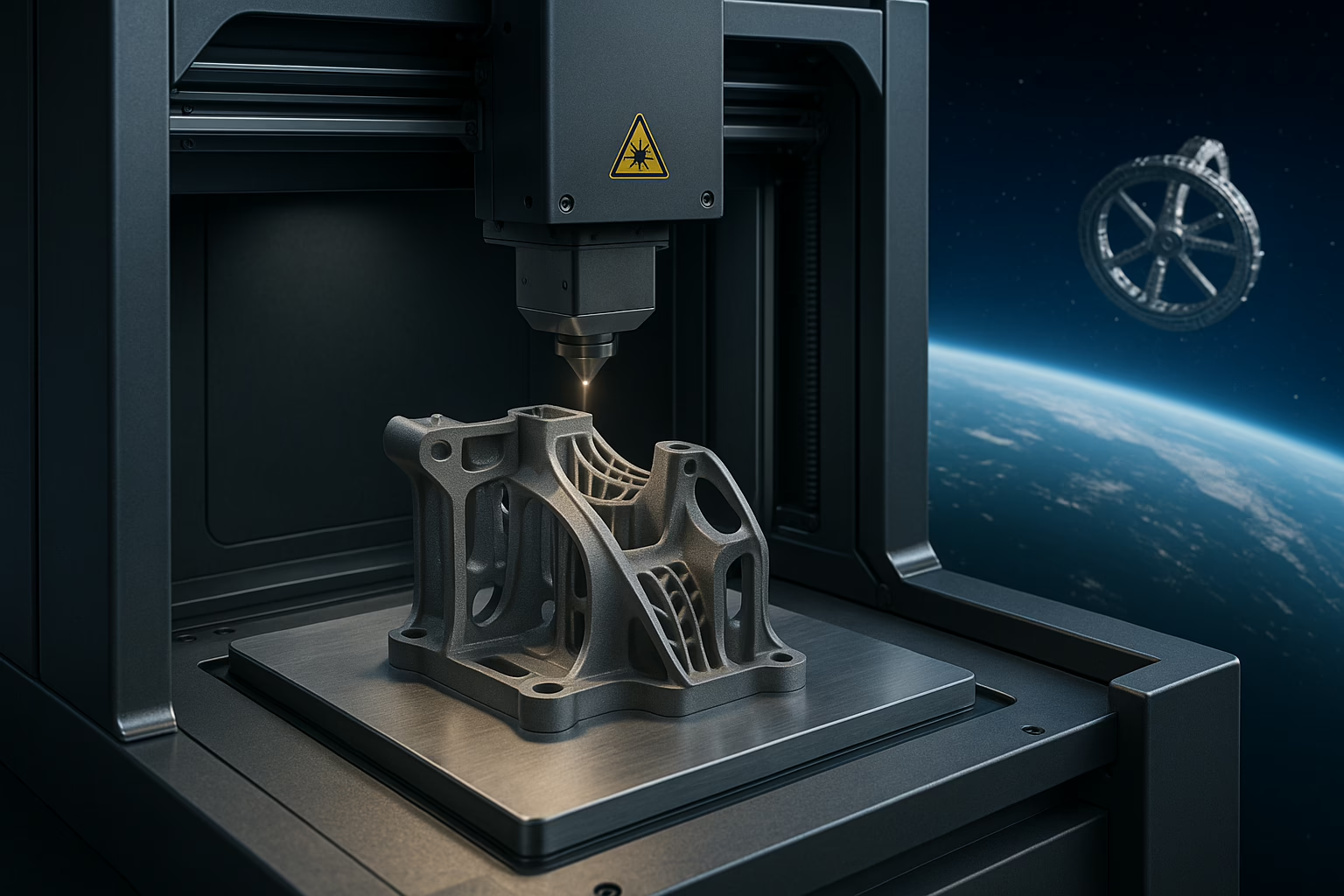

In an age where technology constantly shapes our capabilities, have you ever wondered how we might manufacture parts directly in space? As metal additive manufacturing technology progresses, it opens up exciting possibilities for both terrestrial and extraterrestrial manufacturing, especially within the aerospace sector. With organisations like NASA and the German Aerospace Center pioneering these advancements, the implications for managers, leaders, and tech enthusiasts are profound, as these innovations promise efficiency, cost savings, and enhanced performance.

German Aerospace Center’s Institute for Frontier Materials is at the forefront of developments in metal additive manufacturing (AM) tailored for aerospace applications. Researcher Juri Munk highlights the potential of integrating AM into aeronautics and space exploration. This integration is not just about creating components; it is about rethinking how various challenges in aerospace can be tackled. One remarkable application includes the development of a space propulsion injector made from the new alloy VDM780, which withstands temperatures 100°C higher than the widely used IN718 alloy. Such advancements indicate a promising shift toward more robust aerospace materials that can function in extreme conditions.

Innovative Solutions to Aerospace Challenges

The challenges of space debris and manufacturing logistics are crucial in the realm of aerospace. The Institute for Frontier Materials is innovating solutions to reduce space debris by crafting components with tailored porous regions designed for improved disintegration upon atmospheric re-entry. Such a proactive approach could significantly contribute to a cleaner orbital environment, which is increasingly at risk due to the accumulation of derelict satellites and spent rocket stages. Future satellite missions are set to test these advanced structures, pushing the boundaries of what is possible in space manufacturing.

In addition, NASA is making strides in in-space manufacturing (ISM) through its continuous operations aboard the International Space Station (ISS). With astronauts relying on a complex logistics system for spare parts, the need to manufacture supplies on-demand is becoming ever more critical. NASA’s initiatives have seen successful tests of various 3D printing technologies since 2014, including the 3D printer that enables remote design transmission and part production in microgravity. The Additive Manufacturing Facility (AMF) represents a leap forward, allowing astronauts to print using multiple materials, thus greatly enhancing their capability to sustain long-duration space missions.

Pioneering technologies for the Future

Innovations are not just limited to 3D printing metals; there are ongoing explorations into recycling waste materials to produce 3D printing filaments, particularly from plastic. This dual focus on manufacturing and recycling underscores the urgency to develop stronger plastics and scalable metal processes to meet the needs of future exploration missions. Exploring in-situ resource utilisation is also gaining traction, allowing for the potential construction of habitats using lunar regolith, thereby reducing the need to transport materials from Earth.

Furthermore, the role of bioprinting is starting to emerge in space exploration. Research efforts have aimed at creating human tissues, which significantly supports astronaut health during extended missions. With the challenges of sustaining life in harsh environments, bioprinting could provide a window into long-term survival strategies for astronauts venturing to distant celestial bodies, making it a critical area of focus for future missions.

Challenges and Opportunities Ahead

Despite these advancements, manufacturing in the extreme conditions of space is not without its challenges. The development of appropriate technology that can operate under microgravity and the harsh conditions of space will require continuous investment and innovation. Moreover, companies like SpaceX, Blue Origin, and the European Space Agency are also leveraging 3D printing for various components, making competition in this field fierce. The combination of these advances brings about new questions on scalability, commercial viability, and regulatory considerations as public and private sectors push the envelope in aerospace innovation.

In conclusion, the trajectory of metal additive manufacturing is transforming both aerospace processes and the very nature of manufacturing itself. From developing new materials that withstand harsh conditions to enabling on-demand parts production in space, the implications are profound. Based on the provided materials, as we look ahead, the practical applications of these technologies may not only redefine manufacturing but also pave the way for humanity’s ambitions beyond Earth—an exciting frontier awaits in the cosmos.